HPC-Europa3 visit: Optimising the processing of food

11 April 2018

Miriam Ruiz Ferrández was a recent HPC-Europa3 visitor to Edinburgh who used EPCC resources while being hosted by Napier University. In this article she relates some of her findings and experiences.

Hi everyone! I am a PhD student at the University of Almería, which is located in the south-east of Spain. I spent three months in Edinburgh funded by the HPC-Europa3 programme working on a project entitled: “A Parallel Multi-Objective Algorithm for Optimizing High-Pressure/Temperature Treatments in the Food Industry”. During this research stay, I was collaborating with Professor Ben Paechter at Edinburgh Napier University and I used computing resources provided by EPCC at the University of Edinburgh.

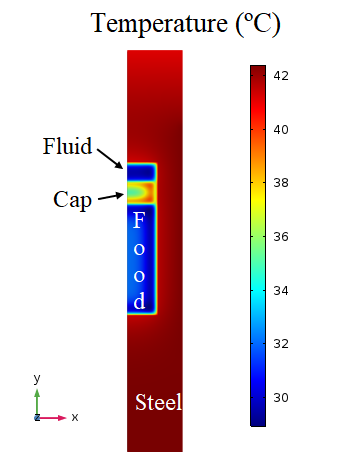

The main idea of this project is to provide a decision tool for food engineers to support them in designing high-pressure and temperature treatments for food processing, a typical system is depicted in the diagram below. Nowadays, the determination of control temperatures and pressures to produce a processed food within predetermined quality levels is accomplished by several trial and error tests. Since the actual target quality levels depend on the country in which they operate, these tests can lead to a considerable waste of time, money and product. The advantage of using our methodology is that it offers a set of configurations computed through the use of a multi-objective optimisation algorithm and, therefore, each time food engineers have to deal with some quality requirements, they can choose from pre-determined pressure and temperature configurations to select the one that best fits them.

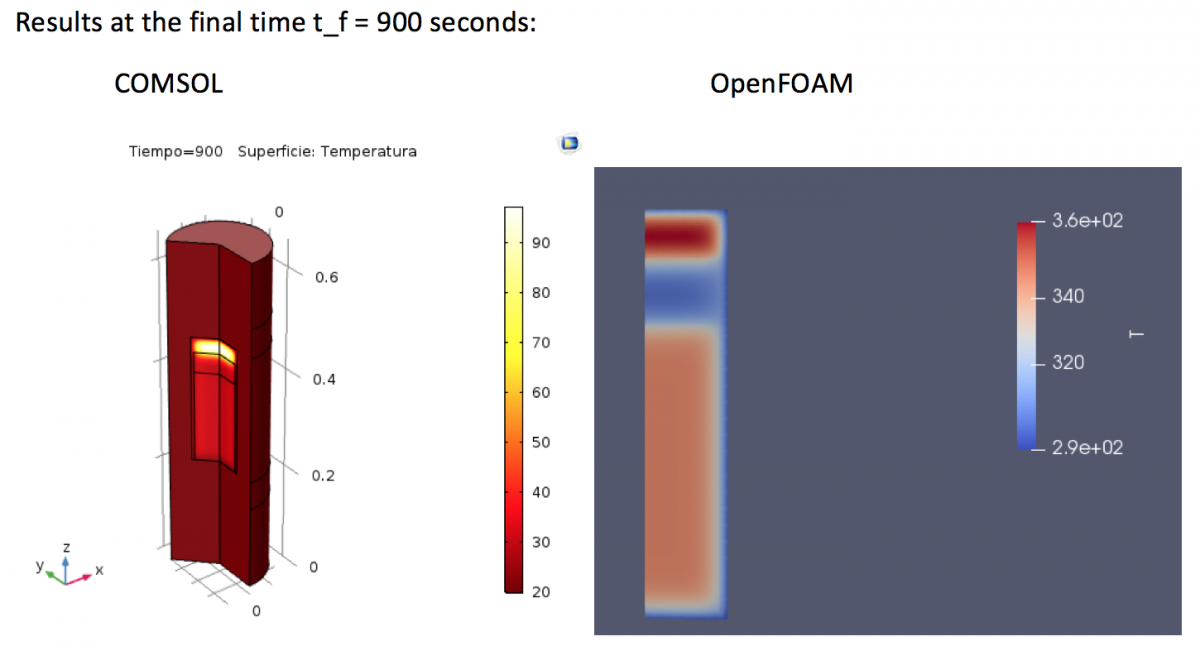

As previous analyses have determined, the most time-demanding task of our optimisation procedure is the evaluation of the objective functions, which consists of numerically solving a partial differential equation system for simulating the high-pressure and temperature treatment. During this visit, those numerical simulations were implemented using the open-source OpenFOAM package and their results were compared with the commercial software COMSOL Multiphysics.

Although the resulting temperatures obtained from both codes were quite similar as schematically shown in the diagram below, the computational time consumed by OpenFOAM turned out to be much greater than for COMSOL, so even using some parallelism strategies OpenFOAM could not compete against the commercial software COMSOL.

Furthermore, a parallel version of the optimisation algorithm based on distributing the evaluations among the available processing units has been proposed and tested. The parallel version allows a significant reduction in the computational time, so that a larger number of points in the solution set and a larger number of iterations could be considered for the optimisation procedure, which translates into an increase in the number of optimal points provided to food engineers and an increment in the method accuracy, respectively.

Finally, in collaboration with Professor Ben Paechter, we have studied some mechanisms to improve the convergence of the optimisation algorithm and the number of optimal points in the final solution. This work has been performed using EPCC's Tier-2 Cirrus HPC Service.

I would like to thank the HPC-Europa3 programme for funding this research stay, and EPCC's staff for providing me with access to its machines, installing all the packages I needed and assisting me during the project. Additionally, I would like to thank Ben Paechter and his research group at Napier University for their hospitality and for making me feel part of the team.

It was a pleasure to discover the beautiful city of Edinburgh and some amazing places in Scotland. I enjoyed it a lot and I will always remember this fantastic experience that made me grow professionally but also personally.

Miriam was an HPC-Europa3 visitor from the 3rd of January to the 3rd of April 2018. If you would like to apply to the programme, see: www.hpc-europa.eu/